When buying a tile blade for a die grinder, it’s important to consider many factors that can affect how well your tool works. The material, size, and quality of the diamonds or abrasives in the blade all make a big difference in how well it cuts, how durable it is, and how versatile it can be. By understanding these factors and how they impact your projects, you can choose the right blade for your needs and make your die grinder last longer.

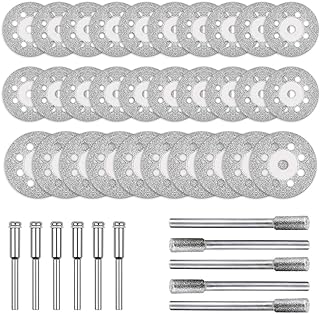

See our guide to the best tile blade for die grinder.

Blade material

When choosing a blade for a tile grinder, it’s important to pick the right material. Diamond-coated blades are the top choice in the industry because they are very strong and cut well. They can easily cut through tough tile quickly and precisely. Even though they cost more upfront, investing in a high-quality diamond-coated blade is worth it because it will last a long time and save you money in the end.

On the other hand, carbide-tipped blades are a good option for those with a smaller budget. They offer a good balance between performance and cost, making them popular among DIYers and professionals. While they are not as durable as diamond blades, carbide-tipped blades can still do a good job when used correctly. However, they may wear out faster and need to be replaced more often, which can negate the initial cost savings. In the end, the choice between diamond-coated and carbide-tipped blades depends on your specific needs, budget, and how often you will be using them.

Blade size

When choosing a blade size for your die grinder to cut tiles, there is a common misconception that bigger is always better. However, it is important to consider the balance between blade size and the complexity of the task. Using a smaller blade can offer more precision, especially for detailed tile patterns, and reduce the risk of damaging the tile.

In contrast, a larger blade may cut faster but can be less maneuverable and delicate, particularly in tight spaces or intricate designs. A smaller blade is more agile and adaptable, resulting in cleaner cuts. The decision of blade size should be based on the specific requirements of the tile cutting job and the desired level of accuracy.

So, when deciding on a blade size for your die grinder, remember that smaller blades can sometimes offer better precision than larger ones.

Tooth count

When choosing a tile blade for a die grinder, it is important to consider the number of teeth on the blade. The tooth count affects how well the blade can cut and its overall performance. A blade with more teeth will give you smoother and more precise cuts, perfect for detailed tile work. On the other hand, a blade with fewer teeth is better for quick, rough cuts.

It’s important to understand your project’s needs and how precise you need to be when choosing the right tooth count for your tile blade. The tooth count also affects how long the blade will last. Blades with more teeth may wear out faster when cutting tough materials. It’s important to find a balance between tooth count and durability to get the most out of your blade.

Getting a quality tile blade with the right tooth count for your project can make a big difference in how well it turns out. Each tooth on the blade plays a part in the cutting process, so picking the right tooth count will give you better results and a better cutting experience.

Arbor size

When choosing a tile blade for your die grinder, it’s important to consider the size of the arbor. The arbor size affects how well the blade works with your tool. A smaller arbor may limit your blade options, while a larger arbor allows for more versatility. Matching the blade’s arbor size to your tool ensures a secure fit and better cutting performance. While it may take some extra effort to find the right blade, the benefits of improved compatibility and efficiency are worth it for DIY enthusiasts and professionals.

Selecting the correct arbor size for your tile blade is crucial for the longevity of your equipment. Using the wrong arbor size can cause premature wear on your tool and create safety risks. By choosing a blade that matches your die grinder’s arbor size, you can achieve better cutting results and prolong the life of your equipment. Prioritizing compatibility and precision in your tool selection leads to smoother cutting operations and a more efficient workflow in the long term.

Cutting speed

When choosing a tile blade for a die grinder, it’s important to prioritize cutting speed over everything else. While durability and cost matter, speed offers unmatched efficiency and precision. Using a high-speed tile blade can boost productivity, saving time and effort on projects. Faster cutting helps prevent damage to delicate materials and ensures a smooth finish for better results.

Focusing on cutting speed when selecting a tile blade can help professionals and DIY enthusiasts improve their work. Speed makes projects easier and more satisfying, leading to a smoother workflow that encourages creativity and innovation. Embracing cutting speed turns simple tasks into opportunities for precision and quality, creating a dynamic environment where efficiency and excellence come together to redefine tile cutting as an art form.

Conclusion

In summary, using a tile blade with a die grinder is a versatile and precise way to cut tiles. It not only makes cutting tiles easier and more accurate but also allows for endless creative options for DIYers and professionals. By investing in a good tile blade and using it with a die grinder, you can improve your skills and get perfect results on every project you tackle. Want more info on bird feeder, check the best bird feeder.