When looking to buy a buffing wheel for a drill to use on metal, there are important things to think about other than just how it looks or how much it costs. Factors like the material of the buffing wheel and whether it will work with different types of drills can make the selection process complicated. Each of these factors is crucial because they affect how well the buffing process will work. By making a well-informed decision based on these factors, you can make sure you get a good product and achieve the best results when buffing metal.

See our guide to the best buffing wheel for drill for metal.

Size and shape of the buffing wheel

When choosing a buffing wheel for a drill to polish metal surfaces, it’s important to consider the size and shape. These factors make a big difference in getting the best polishing results.

The size of the buffing wheel affects how much of the metal it can polish in one spin. A bigger wheel is better for larger areas, saving time on polishing. On the other hand, a smaller wheel is great for detailed work.

The shape of the buffing wheel also matters. Different shapes like tapered, cylindrical, and conical have their own benefits. A tapered wheel is good for tight spots, while a cylindrical one works well on flat surfaces. A conical wheel is perfect for detailed designs.

It’s essential to pick the right size and shape of the buffing wheel for the specific metal project to achieve a professional finish that meets or exceeds expectations.

Material and construction of the wheel

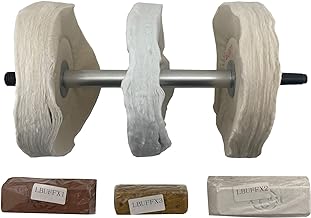

When buying a buffing wheel for metal, it’s important to look at the material and how it’s made. Choosing a wheel made with good materials like cotton, sisal, or wool can make a big difference in how well it buffs. These materials are strong and reliable, so you can get a smooth and effective finish. Also, look at how the wheel is put together. It should have tightly stitched layers to keep it stable and prevent it from falling apart when you’re buffing at high speeds. While a high-quality wheel might cost a bit more upfront, it will give you better performance and last longer, making it a good choice for anyone who enjoys working with metal.

The material and construction of your buffing wheel are important for getting great results when polishing metal. A good wheel makes the buffing process easier and ensures a shiny, polished finish on your metal surfaces. Using a low-quality wheel can lead to problems like uneven finishes, wearing out too quickly, or even being dangerous to use. So, focusing on getting a high-quality wheel is key for anyone who wants to take their metalworking projects to the next level of quality and precision.

Compatibility with your drill

When you’re looking to buy a buffing wheel for your drill to work on metal projects, it’s important to make sure it will work well with your specific drill model. Check the power and speed settings of your drill to make sure they match with what the buffing wheel needs. If they don’t match, it could cause problems and damage either the drill or the buffing wheel. Also, check the size of the chuck on your drill to make sure it can securely hold the shaft of the buffing wheel.

If you don’t pay attention to these compatibility factors, it could lead to disappointing results and frustration when you’re buffing metal.

Choosing a buffing wheel that works well with your drill can make a big difference in how well your metal buffing projects turn out. A high-quality buffing wheel made for drills can help give your metal surfaces a great finish. Look for buffing wheels that are durable and balanced, so they can handle tough polishing jobs. Making sure your drill and buffing wheel work together well isn’t just about fitting them together mechanically—it’s also about getting the best results efficiently in your metalworking projects.

Speed and RPM rating of the wheel

When buying a buffing wheel for a drill to polish metal, it’s important to look at how fast the wheel spins. The speed of the wheel can affect how well it polishes the metal. Choosing a wheel with a high RPM rating can remove imperfections quickly and leave a smooth finish on the metal. But it’s important to find a balance between speed and control to avoid damaging the metal or causing it to overheat.

Having a wheel with adjustable speed settings allows you to work with different types of metal and finishing techniques. Being able to change the RPM based on the job at hand helps you get the best results while protecting the metal. Getting the right combination of speed and RPM in a buffing wheel can really improve the quality of the final finish. This is something to think about when you’re buying tools for metalworking projects.

Polishing compound compatibility and effectiveness of the wheel

When buying a buffing wheel for your drill to polish metal surfaces, it’s important to think about which polishing compound you’ll use. The right compound can make a big difference in how your metalwork looks, making it shine and getting rid of any imperfections easily. Not all polishing compounds are the same, so it’s crucial to pick one that works well with your buffing wheel to get the best results. Making sure the compound and wheel are compatible will help you polish efficiently and achieve a professional finish that makes your metalwork look perfect.

In addition to compatibility, how well the buffing wheel works with the polishing compound is also key to getting the results you want. Investing in a high-quality buffing wheel made for metal projects can greatly improve your final outcome. A good buffing wheel will make sure the polish is spread evenly, giving you a smooth finish without any streaks or uneven spots. When choosing a buffing wheel for your metalwork, focus on quality and effectiveness to make sure your polishing process goes smoothly and gives you beautiful results.

Conclusion

In metalworking, the buffing wheel for a drill is a very useful tool that helps make craftsmanship more precise and refined. When the dull surfaces of metal are polished with this tool, they become shiny and bright, showing how powerful it is. Each time the buffing wheel spins, it not only polishes the metal but also adds a sense of artistry and attention to detail. When the drill and buffing wheel are used together, they turn raw materials into works of art, removing imperfections and bringing out the best in the metal. The buffing wheel acts like a conductor in a symphony, creating a perfect blend of skill and creativity, making a world where excellence is key.