When deciding to invest in air cut off tools, there are important factors to consider. These include power, versatility, durability, and efficiency, all of which can affect how well the tools work and how long they last. In this detailed look, we will explore the key elements that smart buyers should think about before making a decision. This will help them make informed choices and strategic investments in air cut off tools.

See our guide to the best air cut off tools.

Power source (electric, pneumatic, cordless)

When choosing a power source for air cut off tools, you should consider the advantages and disadvantages of electric, pneumatic, and cordless options. Electric models provide steady power and are great for indoor use because they don’t produce emissions. Pneumatic tools are powerful and work well for tough jobs. Cordless tools allow you to move around freely, but their battery life may be limited.

The best choice depends on the specific requirements of the job. Electric tools are good for constant use, while pneumatic tools are better for tasks that need a lot of power. Cordless tools are portable but might not last long enough for extended use. It’s important to understand the unique qualities of each power source when picking the right air cut off tool to meet your needs and boost productivity in different work settings.

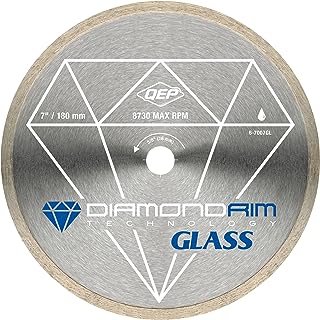

Disc size and compatibility

When buying air cut off tools, it’s important to think about the disc size and which discs will work with the tool. The size of the disc is key in how well the tool can cut different materials. A bigger disc can cut a wider area, but it’s important to pick a size that matches the tool’s power output. Being able to use different discs not only makes the tool more versatile, but also helps you cut with more accuracy and efficiency.

To choose the right disc size and compatibility, you need to think about what you’ll be using the tool for and how precise you need to be. Having air cut off tools with different disc options gives you the flexibility to handle different cutting tasks easily. Making sure the tool is compatible with different discs means you can switch between projects smoothly without losing efficiency or quality. By thinking about these things, you can improve your cutting experience and make your projects successful.

Speed and control settings

When you’re looking to buy air cut off tools, it’s important to consider how the speed and control settings work together. These settings are key to how well the tools perform and how efficiently they can cut through different materials. The speed setting determines how fast the blade will cut, while the control setting helps you make precise cuts. Finding the right balance between speed and control is crucial for improving the quality of your work and your overall experience using the tools.

By getting the speed and control settings just right, you can turn cutting into a skillful art. You’ll be able to make precise cuts no matter how thick or dense the material is. Being able to adjust these settings based on the job at hand gives you the confidence and finesse to handle a variety of tasks. Choosing air cut off tools that offer a perfect balance of speed and control will lead to better results and enhance your performance in all kinds of cutting projects.

Ergonomics and comfort

When buying air cut off tools, focusing on ergonomics and comfort can really improve your experience. Having a tool that feels good in your hand and allows for good posture can help prevent fatigue and strain when using it for long periods of time. The design of the tool should make it easy to grip and reduce vibrations to lower the risk of hand and arm injuries. By investing in a comfortable air cut off tool, you are protecting your physical health and also improving your work efficiency and accuracy.

Additionally, thinking about comfort when choosing a tool can boost your productivity and job satisfaction. A comfortable tool that fits well in your hand and has easy-to-reach controls can make your work flow smoother and reduce downtime. By picking an air cut off tool that meets your comfort needs, you are setting yourself up for success and making your tasks easier and more enjoyable. In a competitive market with lots of choices, making comfort a priority in your decision-making can really make a difference in your overall experience and performance.

Durability and reliability

When buying an air cut off tool, it’s important to prioritize durability and reliability in your decision-making process. Having a tool that can last a long time and consistently do the job well is crucial for professionals and hobbyists. A sturdy air cut off tool not only saves money in the long run but also gives you confidence and precision when cutting.

When looking at how reliable an air cut off tool is, don’t just focus on the initial cost. Think about the overall quality and reputation of the brand. Choosing a well-known brand that makes reliable tools may cost a bit more, but knowing your tool won’t let you down when you need it most is priceless. Quality craftsmanship and strong materials are key to reliability in power tools, so it’s important to prioritize these things when buying.

Conclusion

In today’s world, where being precise and efficient is key, air cut off tools are really important for professionals and DIY enthusiasts who want to easily work with tough materials. These tools are powerful and can be used in many different ways, making them essential in any workshop or job site. As we explore all the ways these tools can be used, one thing is certain – their speed, accuracy, and dependability make them a crucial part of any craftsman’s collection of tools, changing how we think about cutting things and setting higher standards for power tools. Want more info on sculpture for wall, check the best sculpture for wall.